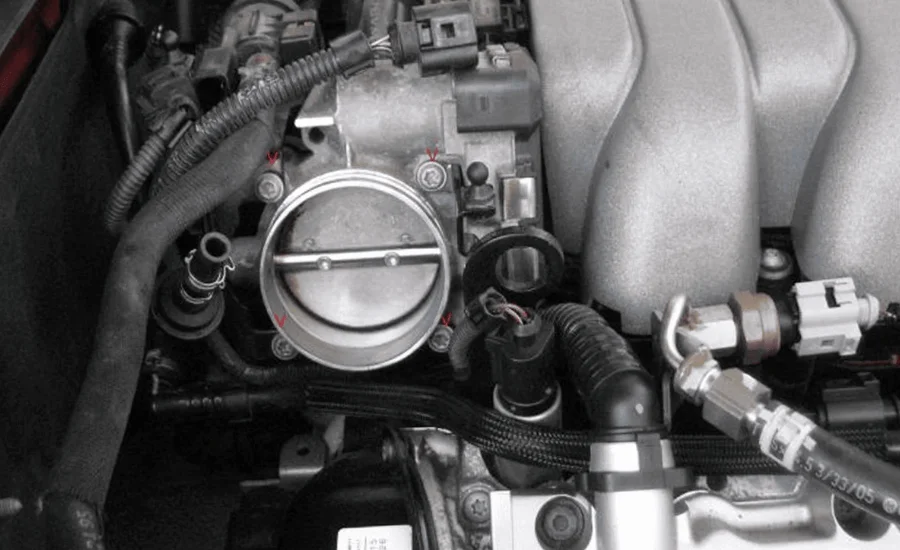

The K25LP throttle control is a crucial component in modern machinery, designed to manage engine speed and power adjustments with precision. Whether you’re a seasoned professional or a DIY enthusiast, understanding its features, installation, maintenance, and troubleshooting can significantly enhance your equipment’s performance.

This guide provides an in-depth look at the K25LP throttle control, covering its key aspects to help you get the most out of this essential component.

Introduction to the K25LP Throttle Control

The K25LP throttle control is engineered for precision in managing engine speed and power output. Its robust design and user-friendly interface make it a valuable tool in various applications, from industrial machinery to recreational equipment.

The K25LP throttle control ensures smooth operation and reliability by accurately regulating engine performance, making it an indispensable component for effective machinery management.

Key Features of the K25LP Throttle Control

Several key features define the K25LP throttle control:

Precision Management: The throttle control allows for fine engine speed and power adjustments, ensuring that the machinery operates within its optimal parameters.

Durability: Constructed from high-quality materials, the K25LP throttle control is built to withstand the rigors of demanding applications. This durability ensures a long service life, even in challenging environments.

User-Friendly Design: The K25LP throttle control’s design simplifies adjustments and operation, making it accessible to both professionals and hobbyists. This ease of use is crucial for maintaining effective control over engine performance.

These features collectively ensure that the K25LP throttle control delivers reliable and efficient performance, making it a valuable asset in various applications.

Importance of the K25LP Throttle Control

The K25LP throttle control plays a vital role in machinery by regulating engine speed and power output. Proper management of these parameters is essential for achieving optimal performance and efficiency.

By ensuring precise control, the K25LP throttle control helps maintain smooth operation, prevent engine overload, and extend the lifespan of the equipment. Effective use of the throttle control contributes to overall machinery reliability and performance.

Installation Steps for the K25LP Throttle Control

Proper installation of the K25LP throttle control is crucial for its effective operation:

Prepare the Machinery: Ensure the equipment is turned off and safe. dissociate any power sources to help accidents.

Locate the Installation Point: Refer to the manufacturer’s guidelines to identify the correct location for the throttle control. Proper placement ensures optimal functionality.

Attach the Throttle Control: Securely mount the K25IP throttle control to the designated points. Ensure all connections are aligned and tightened as specified.

Connect the Wiring: Follow the wiring diagram provided by the manufacturer to make the necessary electrical connections. Proper wiring is essential for the throttle control to function correctly.

Test the Installation: After installation, perform a test run to verify that the K25IP throttle control operates as expected. Check for any irregularities and make adaptations as demanded.

Electrical Connections and Wiring

Accurate electrical connections are essential for properly functioning the K25LP throttle control. Ensure that all wiring is correctly connected according to the manufacturer’s specifications. Improper wiring can lead to malfunction or damage. Double-check connections to ensure they are secure and properly insulated. If any issues arise, consult the wiring diagram or seek professional assistance.

Testing the K25LP Throttle Control

Testing the K25LP throttle control after installation is crucial to confirm its proper operation:

- Check Functionality: Verify that the throttle control adjusts engine speed and power as intended. Test various settings to ensure consistent performance.

- Monitor Performance: Observe the engine’s response to throttle adjustments. Look for any signs of irregular performance, such as hesitations or fluctuations in speed.

- Adjust as Needed: If the throttle control does not perform as expected, make necessary adjustments to calibration or installation to optimize its functionality.

Routine Maintenance Practices

Regular maintenance is critical to ensuring the longevity and performance of the K25LP throttle control:

- Inspect Regularly: Conduct routine inspections to check for signs of wear or damage. Look for cracks, leaks, or abnormal wear on moving parts.

- Keep Clean: Debris and contaminants can affect the throttle control’s performance. Regularly clean the component to prevent buildup and ensure smooth operation.

- Apply Lubrication: Use the recommended lubricants to reduce friction and wear on moving parts. Proper lubrication helps maintain optimal performance and extends the component’s lifespan.

Cleaning and Lubrication Tips

To maintain the K25LP throttle control:

- Clean Regularly: Remove debris and contaminants from the throttle control. Use appropriate cleaning agents that do not damage the component.

- Lubricate Moving Parts: Apply lubricants as specified by the manufacturer. Proper lubrication reduces friction and prevents premature wear, ensuring the throttle control operates smoothly.

Calibration and Adjustment Procedures

Calibration is necessary to maintain accurate performance:

- Check Calibration: Periodically verify that the K25LP throttle control is correctly calibrated. Accurate calibration ensures proper engine speed and power adjustments.

- Adjust as Necessary: Follow the manufacturer’s guidelines to make any necessary adjustments. Proper calibration helps in achieving optimal performance and efficiency.

Troubleshooting Common Issues

Address common issues with the K25LP throttle control:

- Inaccurate Speed Adjustments: Ensure the throttle control is correctly calibrated. Check for any mechanical problems that may affect performance.

- Performance Issues: Inspect the component for signs of wear or damage. Replace any defective corridor to restore proper operation.

- Electrical Problems: Verify wiring connections and inspect for any faults. insure all electrical factors are performing rightly.

Conclusion

The K25LP throttle control is a pivotal component in ensuring precise engine management across various types of machinery. By understanding its key features, following proper installation procedures, and adhering to regular maintenance practices, you can significantly enhance the performance and reliability of your equipment.

Read more blogs at Techopedia